It is not our job to talk. WE ACT!

Performance through know-how,

passion and a spirit of innovation.

Sustainability, performance

of the highest quality,

tailored to your needs.

It is not our job to talk. WE ACT!

Performance through know-how,

passion and a spirit of innovation.

Sustainability, performance

of the highest quality,

tailored to your needs.

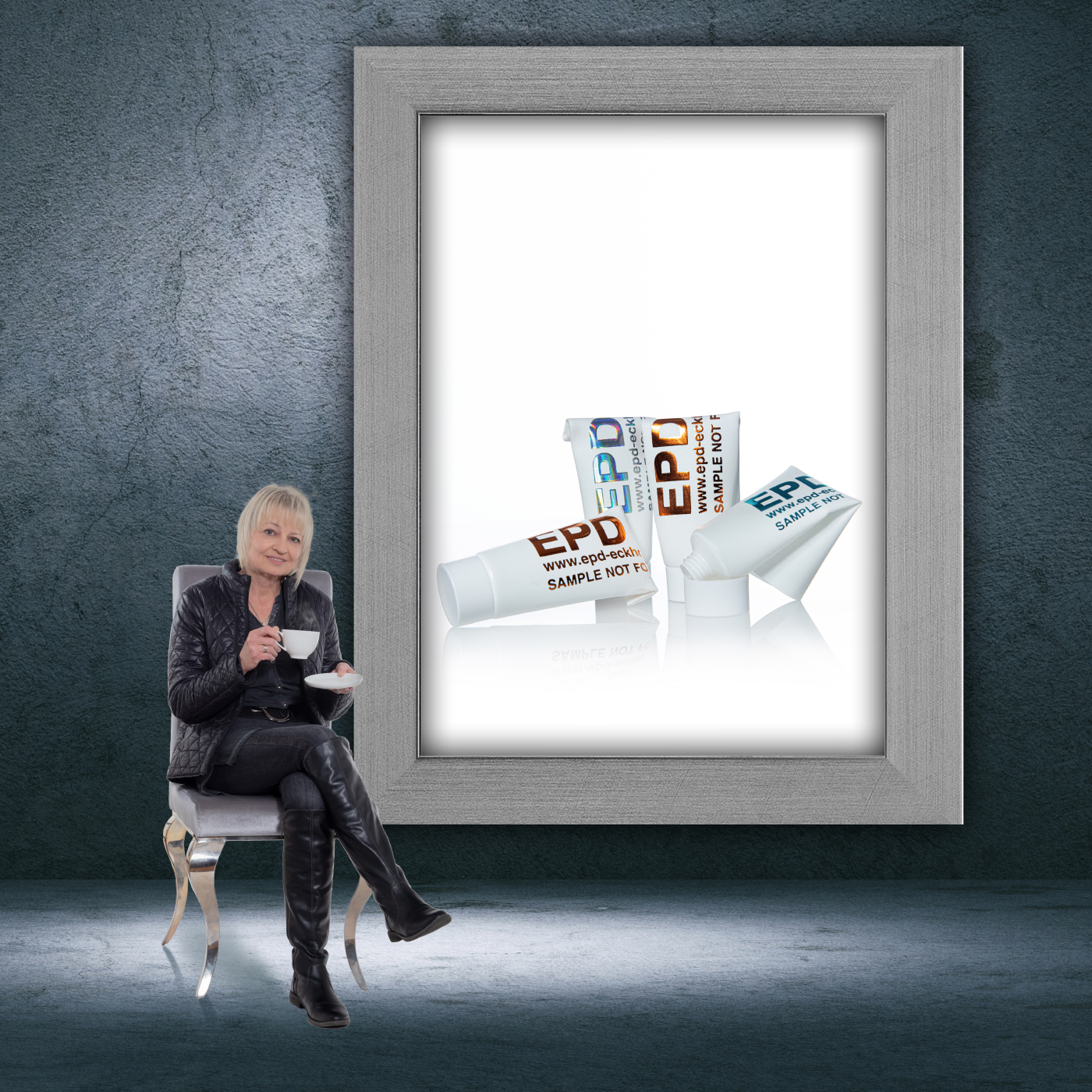

EPD-ECKHOFF

Our core competencies are screen printing, pad printing, hot stamping, heat transfer, haptic screen printing as well as custom applications.

Our international customer base includes very well-known companies from the fields of automotive, mechanical engineering, medical technology, cosmetics and writing instruments.

Screen printing

It is a stencil-like process in which color is applied directly to the material to be printed through a mesh fabric using a rubber squeegee.

One of the main advantages lies in the control of the paint application by influencing the fineness and thread thickness of the mesh fabric.

As with all other sectors of decoration, all pre-stages here too all the preliminary stages and necessary tools are manufactured in-house.

We produce large-format components using the lift-off method and round shapes using the roll-on method. Cylindrical and conical shapes can be decorated up to 360°.

Multi-colored prints are the standard and are positioned mechanically using a register mark or aligned with the help of photo sensors in conjunction with state-of-the-art stepper motors

Pre-treatments such as cleaning, ionization and flaming are integrated, as are post-treatments.

For example, the completion of the component with a second building block (mascara wiper assembly).

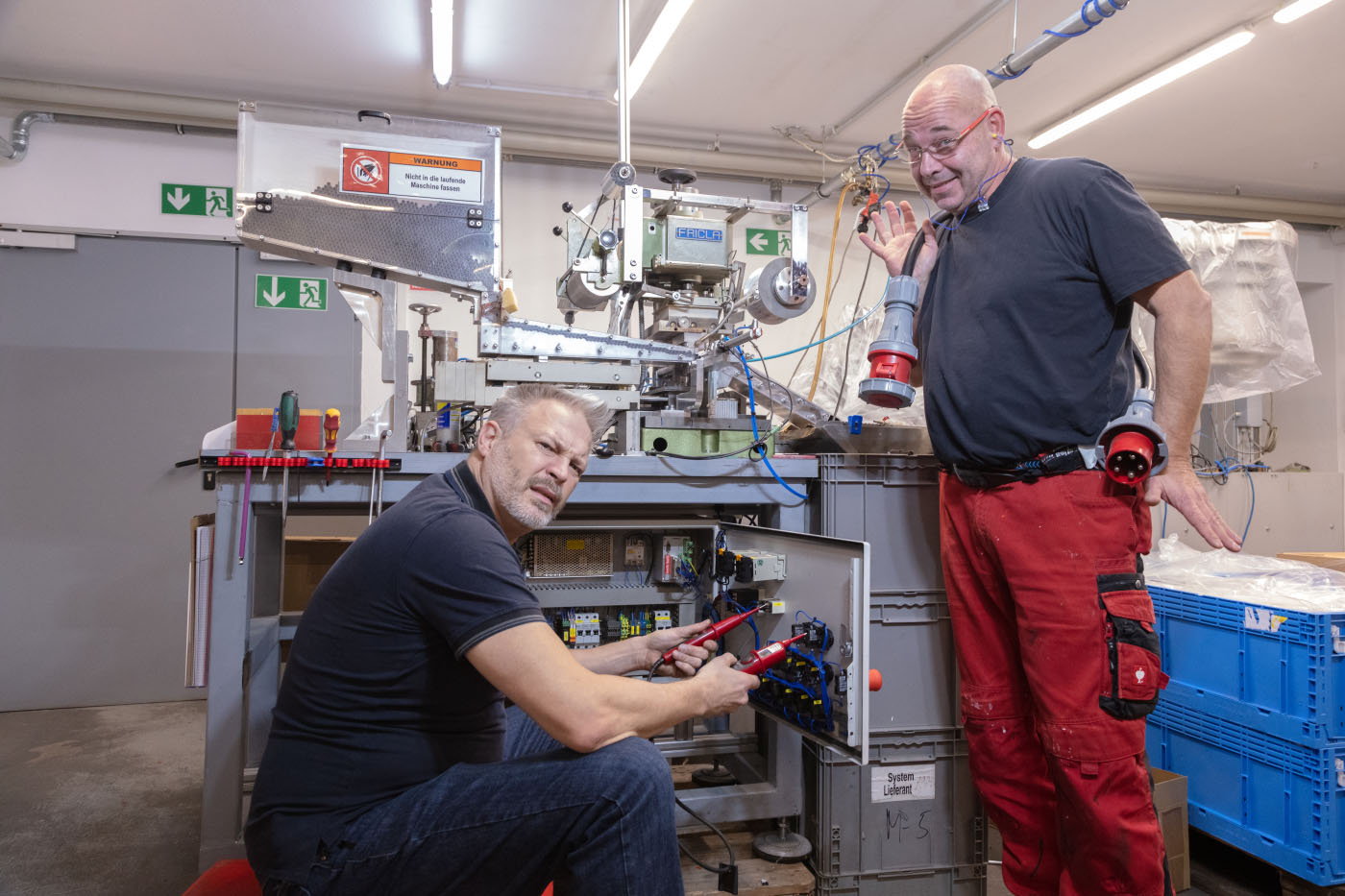

Since 12 years, all systems have been manufactured by an external reputable machine builder under our own supervision.

In this way, all the benefits of a wide variety of printing machine manufacturers are tailored to our needs.

The very close communication with our technology and application thus creates the most modern and user-friendly hardware.

3D Screen printing

This decoration technique has been protected by our European patent EP 2 279 865 B1 since 2009.

It involves making a printed image both tactile and visible.

It can be applied to almost any material and is exclusively implemented through screen printing.

The height of the print can be increased through multiple passes.

Unlike traditional Pantone color selection, color is defined through the use of embossing foils.

In a separate step, it is possible to apply a color component solely to the surface of the tactile elements.

This means that a wide range of colors is available, as well as the use of special metallic or holographic foils to make your product stand out.

Another option is the integration of metal flakes, which greatly enhance the product and serve as eye-catchers. This option cannot be realized with other decoration techniques in this form.

We produce on glass, metal, all types of plastic, as well as cellulose or bio-based materials.

The decoration is extremely durable and can be applied to tubes or similarly mechanically stressed articles.

This technique is not only visually unparalleled, but also offers enormous benefits to users, as the tactile elements can provide a grip function, making the surface similar to sandpaper. As a result, the user can effortlessly open or close the products even with creamed hands.

Pad printing

There are almost 500 years between letterpress printing and the first attempts of today’s pad printing. The first steps with roller inking began in 1800, until early 1900 when watchmakers refined the process.

In 1968, the process was authorized for industrial use.

Pad printing is an indirect gravure printing process.

The printing image, consisting of depressions in the printing plate, is adapted to the various printing substrates and customer requirements.

In the first step, the printing plate is wetted with ink and in the second step, the ink is removed from the depressions, leaving only the printing image.

Now, the transfer of the printing image to the medium to be decorated takes place using silicone rubber pads.

Sounds easy, but there are many parameters to consider, from reproduction work and simulation to film production.

The selection of exposure and printing plates with respect to the desired color intensity, the necessary distortion in the case of special product shapes to be printed, the selection of pads in terms of shape and Shore hardness, and the necessary pretreatments such as cleaning or reducing surface tension values for optimal color adhesion, and post-treatments.

All preliminary stages, from printing plate production to necessary recordings, are produced in-house.

Pad printing is used on complex surfaces due to its flexibility and is characterized by the ability to reproduce very fine details.

Printing such very small and fine motifs is difficult to handle with other printing methods.

Multicolored motifs are always feasible with special equipment with register accuracy of 0.1 mm.

We have manual machines with up to 5 integrated printing units and semi-automatic or fully automated production lines.

As mentioned before, each application has its justification.

For this reason, we use all common manufacturing processes to make the right choice.

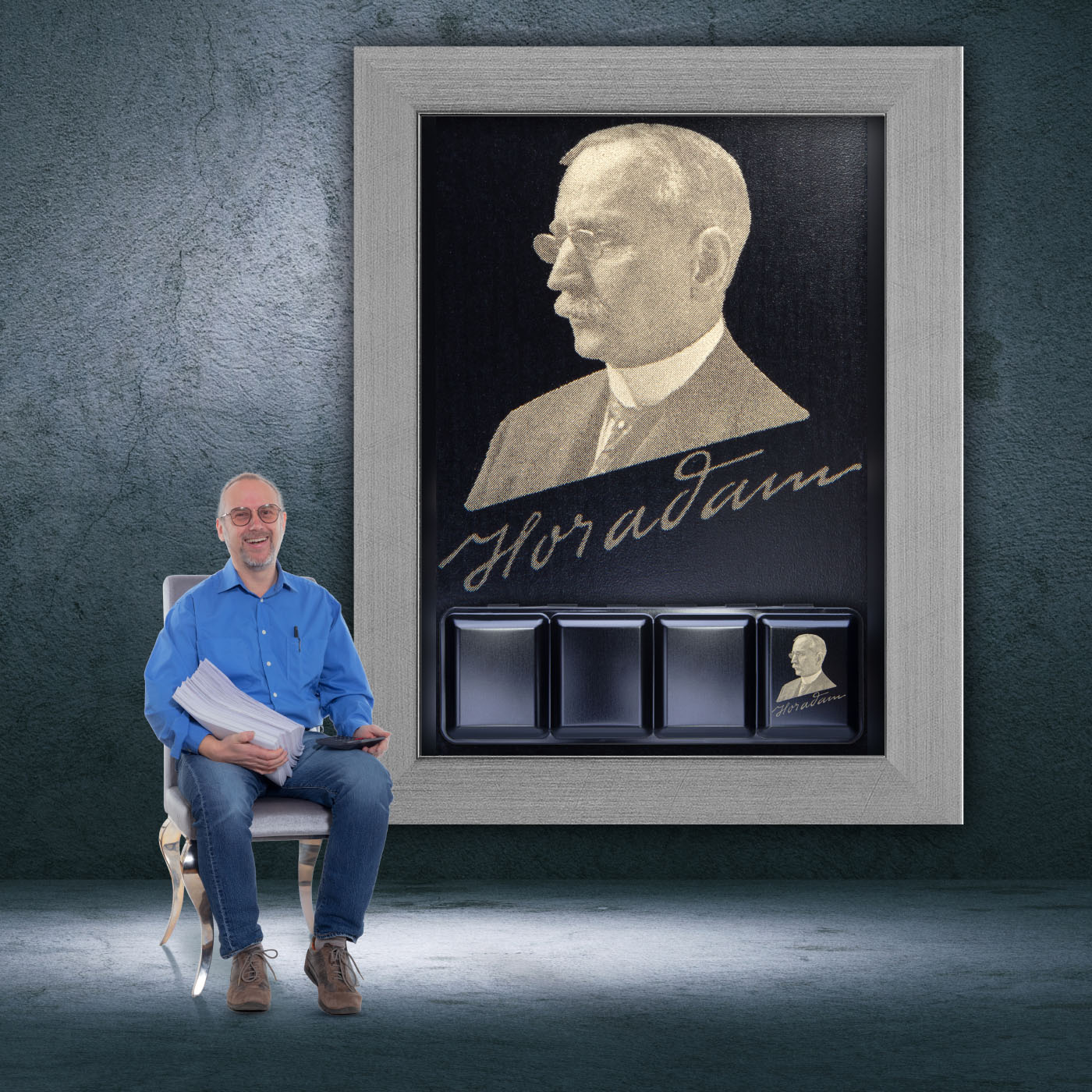

Hot stamping

Hot foil stamping is an additional decorative enhancement that originated during the era of letterpress printing.

Initially, this technique was used to embellish paper and cardboard.

Nowadays, it can be applied to almost all common materials.

If a material cannot be processed, a special adhesive can provide a solution.

Depending on the design, shape, and application of the item, either brass or steel stamps or silicone stamps with or without contours are used.

Since each variant of hot stamping stamps has its own justification, we choose the right one for your needs.

By applying pressure and temperature, the contact between the adhesive of the foil and the material is enabled.

Whether in the platen press method or the roll-on method up to the curve-controlled rolling of conical components, we have 33 years of application expertise.

This process is also used for the final refinement of our patented haptic decoration.

Initially only in high-gloss gold and silver tones, also in matte finishes.

Today, it is also available in various colors, including custom-made holographic and laser effects.

Full-area finishing as an alternative to metallization or in carbon optics is also very popular.

Another development has emerged in the last 30 years with a related technology called heat transfer.

Heat transfer

All materials used are EN71-3 REACH compliant.

The production of HIGH-END films is certified to ISO 14001 and GMP compliant.

The construction of a heat transfer film is carried out using deep printing technology on a carrier layer with the appropriate release and protective layers, as well as the color layers and finally the adhesive layer defined for the material to be decorated.

Up to seven colors are possible, so with CMYK there is also the option of backing special colors or partial white areas. Designs with partial adhesive layers can also be produced and metallized in a separate process.

The transfer of the heat transfer film is carried out using hot stamping technology with silicone tools.

We have been using this technique for almost 30 years, initially in the writing instrument sector, but today in various industries from automotive to cosmetics.

A heat transfer film is essentially a further development of a custom-designed single-image hot stamping foil, both in terms of the design and the material of the component to be decorated.

Since a direct connection is made with the material, there is no foreign body impression as with a label.

Furthermore, the adhesive strength cannot be compared in any way to that of attaching a label.

We offer a full-service package, from concept development, design, and color matching to approval security. Our films are produced by two external business partners with whom we have had a business relationship for almost 30 years.

You receive everything from a single source, from development to the finished decorated product.

Individual solutions

Do you have a new idea or an interesting task?

Decorations on special materials or on particularly shaped structure? Do you need a food-compliant refinement or special effects?

These are exactly the challenges and tasks that we love and thrive on. That’s why we achieve finely crafted results together with our customers for the success of us all. TEAM Do you want to give weight to actions rather than words and pictures? Then don’t hesitate to see for yourself and put us to the test with your challenge.

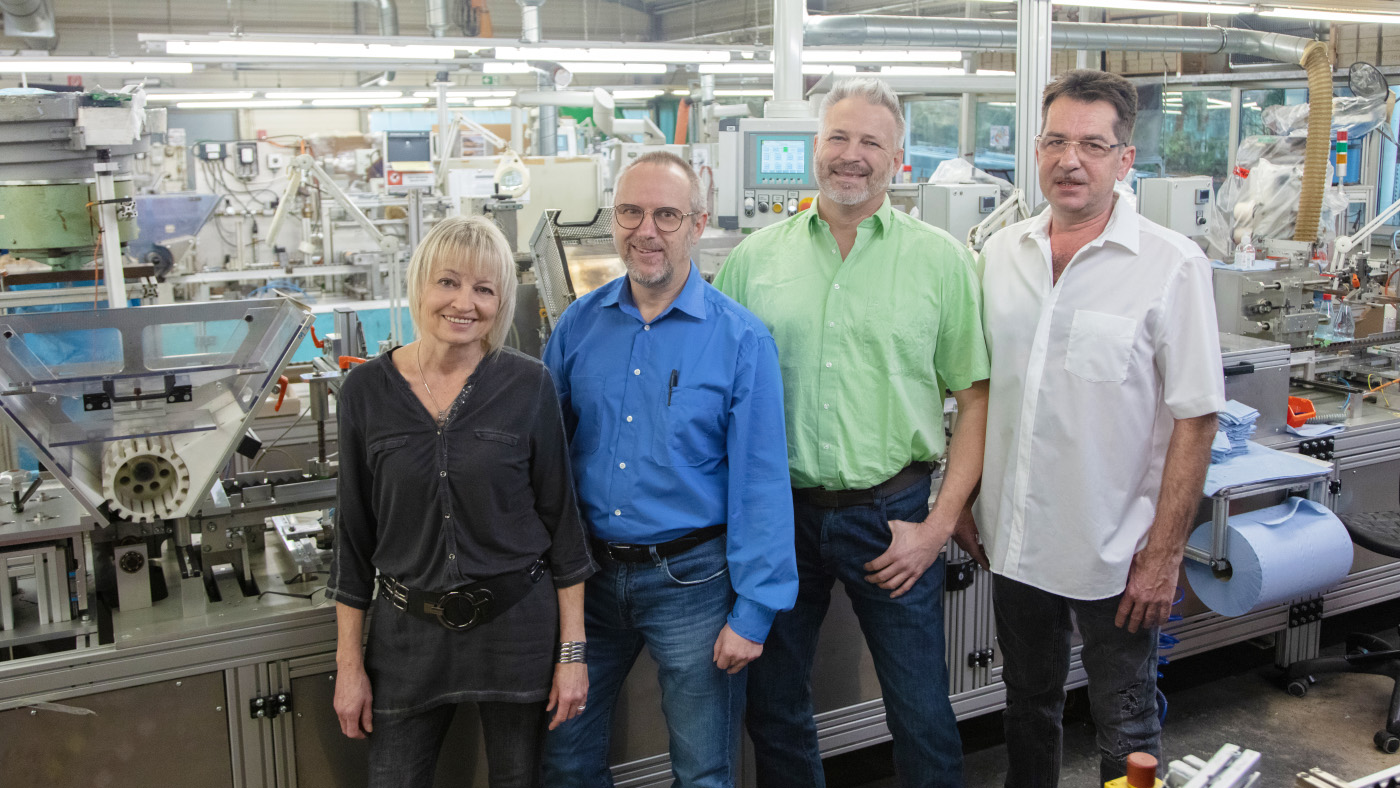

TEAM

Möchten Sie Taten statt Worte und Bilder Gewichtung geben?

Dann zögern Sie nicht, sich selbst ein Bild zu machen und stellen Sie uns mit Ihrer Herausforderung auf den Prüfstand.

Our Quality Standards

The quality of a product is higher when the demands of the customer are met to the fullest extent possible. Therefore, our quality assurance measures accompany a product from delivery to production to delivery to the customer.

- Our quality checks take place before, during, and after the production process.

- A target-actual comparison, trend recognition during sample testing, and any necessary rework or sorting are carried out.

Our quality control aims to keep the dispersion of characteristic values within limits, which are influenced by the „4 M factors“: Material, Machine, Man, and Method.

That is why the delivered goods are subjected to an incoming goods inspection, our machines are subjected to regular maintenance and inspections, our well-trained staff is always kept up to date and manufacturing processes, work sequences and test conditions are examined in detail.

Similarly, the strictest environmental standards are also included in our quality assurance measures.

This is based on our principles:

Principles of DIN EP

Customer focus

In order to operate an effective and sustainable QS system, orientation towards the needs of our customers is particularly important to us. Therefore, the collection of these is an essential part of our daily work.

Leadership

One of the tasks of our company management is to ensure the effectiveness of our QS system in the long term. The company management thus supports the achievement of quality goals, the satisfaction of our customers and thus also the satisfaction of our employees.

Employee Involvement

In order to continuously and effectively optimize our processes and structures, our competent, motivated and committed employees are required. A corresponding motivation of these makes our work easier and thus also the achievement of our goals.

Improvement

Due to constantly growing requirements, the continuous improvement process is a major part of our work. In order to maintain a high level of performance and competitiveness, continuous development of our processes is one of our main guidelines.

Relationship management

The focus here is on the benefit of our customers, suppliers and our company. Targeted control of relationships among each other has a lasting effect on everyone’s success

Machine Park

Screen Printing:

11 fully automatic machines equipped with up to three printing stations each. All machines can be complemented with various pre- or post-treatment systems or other handling systems.

3 semi-automatic printing machines

2 manual screen printing machines

Pad Printing:

1 fully automatic five-color machine

2 fully automatic three-head machines

8 pneumatic machines

4 mechanical machines

Sustainability, Environment and safety

Heat transfer foils and hot stamping foils

All materials used are EN71-3 and REACH compliant.

The production of the HIGH-END films is ISO 14001 certified and GMP compliant.

Energy management

We have one of the most efficient compressor systems from Kaeser in operation and heat the entire production with heat recovery.

Energy saved has a positive effect on our price and cost structure

And we save resources.

Sustainability

We have been helping companies introduce cellulose as a base material for 7 years as a substitute for plastics and, with the knowledge advantage gained as a result, are leaders in decoration on cellulose.

Safety

By constantly monitoring and modernizing our systems and processes, we are always up to date with the latest safety technology.

The protection of our employees and the environment is very important to us.

Innovations

We always look far beyond the horizon.

Without neglecting day-to-day business in the slightest, our focus is always on being able to offer our business partners new innovations in order to be able to differentiate their products from the market.

What is better suited to this than our haptics, and print with fragrances of your choice (which are activated by touch). Printing vitamins which, for example when in contact with water, change their color after 30 days.

Printing temperature-dependent color changes, printing electrically conductive colors.

And antibacterial and antiviral full-surface sealing with Nano silver.

Trade show

Company History

01/01/1990 Company founded in Weißer Weg, 90491 Nuremberg Hot stamping and pad printing

06/01/1993 Company relocation to Max-Brod-Straße 11, 90471 Nuremberg Hot stamping, pad printing, and heat transfer

01/01/2005 Company relocation to Liebigstraße 7, 91126 Schwabach Hot stamping, pad printing, heat transfer, and screen printing

07/01/2009 Company expansion at the current location

05/01/2014 Start of building our own screen printing equipment

2019 Second location in Schwabach with over 1,000 sqm added Complete reorientation of all sectors

2021 Introduction of Lean Management due to COVID-19 Second location is closed. Main location is modernized to improve efficiency. New ERP system is introduced.

2022 Product expansion in the automotive, medical technology, and mechanical engineering sectors.

2023 Acquisition and integration of Fritz Claussner, FRICLA – hot stamping machines

Jobs

We are always looking for motivated employees to join our long-standing team. Whether you’re a media technologist, machine operator, or someone looking to switch careers, we welcome you to apply. We provide thorough training and assign a coach to guide you through your tasks.

To apply, please send your resume to recruiting@www.epd-eckhoff.com

Contacts

communication is key

Office Management

Marion Galleitner

+49(0) 9122 1855011

m.galleitner@www.epd-eckhoff.com

Chief Financial Officer

Michael Krauß

+49(0) 9122 1855012

m.krauss@www.epd-eckhoff.com

Chief Executive Officer

Detlef Eckhoff

+49(0) 9122 185500

support@www.epd-eckhoff.com

EPD-ECKHOFF GMBH – Liebigstraße 7 – D 91126 Schwabach

Tel. +49 (0)9122 185500 – support@www.epd-eckhoff.com

EPD-ECKHOFF GMBH

Liebigstraße 7

D 91126 Schwabach

Tel. +49 (0)9122 185500

support@www.epd-eckhoff.com